Prints & Giggles: How I Hunt Models

Ever spend 20 minutes searching, download a “perfect” model, then waste two hours and half a spool of filament (hopefully not the good stuff) learning it was missing something critical? Same. I wanted to share why I believe Printables by Prusa Research is the best 3D printable models site. I also share some of my thoughts on reviewing models to print. Most of the time, I can find models on Printables to fix an issue. If not, I tend to design my own solution. It’s how my 10‑inch rack mount happened—I measured the hardware, modeled it in OpenSCAD, and shared the full build: https://printpresssew.com/myog-approach-to-the-10-inch-rack-mount.

Quick note: I’m focusing on Printables, Thangs, and Thingiverse. I’m intentionally not covering other sites here.)

Short version: I browse a few platforms, but Printables is home base. The community is active, the rewards are fun, analytics are genuinely helpful, and the workflow fits how I build and print. I’ll show you why.

TL;DR – The quick map

| Platform | Best For | Standout Features | Watch‑outs |

|---|---|---|---|

| Printables | Everyday printing, community feedback, publishing your own work | Designs & Makes, rewards/points, flash contests, Open in PrusaSlicer, robust analytics | None major—just remember to read the model notes |

| Thangs | Hunting across the entire web, engineering parts, parametric bases | Geometry‑aware search, great discovery, supports many file types | Results vary by source; still vet the original listing |

| Thingiverse (the OG) | Legacy projects, remixes, deep archive | Massive history, lots of remixes/makes | Some listings are dated, sparse notes; double‑check files and licenses |

Why Printables is my home base

I hang out on Printables because it feels like a maker space that actually ships. The incentive structure is smart, the search is solid, and the features match how I print in real life.

Designs & Makes (the two‑way trust signal)

Printables bakes in two sides of a project: the original model (“Design”) and the real‑world prints (“Makes”). That second part is gold. Seeing photos of other people’s results—with their material, layer height, and little “gotchas”—is the difference between a confident one‑and‑done and a mystery reprint.

Bonus: I also use Makes to preview color schemes. Building something like a Voron? Browsing other folks’ Makes is basically a live swatch book—you can see how black/gray/orange pops versus stealthy all‑black or neon accents before you buy filament.

Rewards/points that actually feel rewarding

You can earn points for adding useful things—publishing designs, uploading makes, contributing to the community. Those points can be redeemed for filament, vouchers, printers, and other rewards. Is it going to pay your rent? No. Is it a fun nudge to contribute more? Absolutely. I’ve found it keeps me sharing, documenting, and improving—because that little feedback loop makes it worth the extra 60 seconds to post a make with notes.

Fair play: when you redeem points, the Printables team reviews activity to keep folks from gaming the system and to protect the rewards pool.

Badges & levels: you can also level up your profile with badges—from simply visiting the site to uploading models and posting Makes—so your profile credibility grows as you contribute.

Flash contests keep ideas flowing

Flash contests are short, themed challenges that spark fast, useful uploads. I love these because the prompts push me to solve small, real problems I might’ve ignored—then I end up with a design other people can actually use. Even if you don’t enter, browsing contest entries is a great way to find fresh models that print well.

“Open in PrusaSlicer” (chef’s kiss)

If you run PrusaSlicer, the Open in PrusaSlicer button is such a good quality‑of‑life feature. Click the button and jump right into PrusaSlicer, ready to slice and send the model to your printer. This feature works with STEP, STL, and 3MF files. 3MF files are commonly used to help export print settings or model orientations if they need to be somewhat custom (odd angles, model painting, etc.).

Caveat: not all 3MFs open the same. Files exported from other slicers or older toolchains can be… temperamental. If a 3MF acts weird (missing parts, odd supports, or errors on load), try: 1) update PrusaSlicer, 2) import it as model only and re‑apply your own profiles, or 3) ask the creator for a plain STL/STEP. Worst case, drop the mesh into a fresh project and rebuild the settings.

Analytics that help you get better

Printables gives you solid analytics on your designs—views, downloads, likes, makes. It’s a fun way to watch how your skills and models resonate over time—little internet brownie points that actually teach you what lands. If I were doing this for a living, those trendlines would be gold: which problems get the most downloads, where Makes spike, and what deserves a v2. For now, I haven’t shipped a v2 yet; analytics are my nudge to plan one when the signal is clear.

My profile (and why I link it)

I’m @techis on Printables—different handle than the blog, but it’s me. That’s where my models live, and it’s the best way to see the designs in the wild: https://printables.com/@techis. Linking it from my blog boosts trust and gives you a clear next step if you want to try something I mention here.

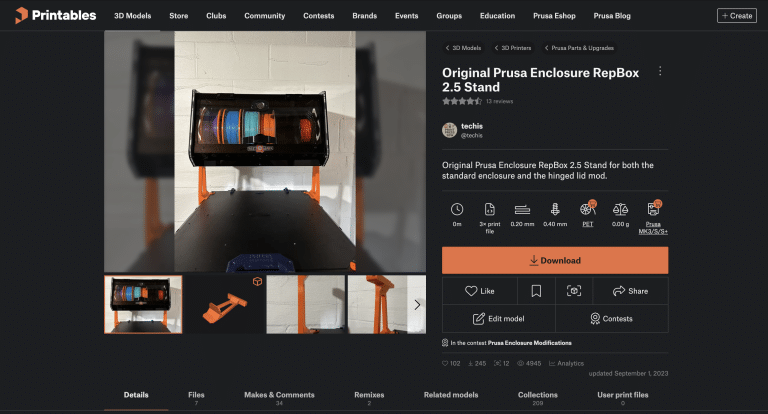

The pride of shipping something people use (my “best” model)

There’s nothing like watching a design leave your bench and show up in someone else’s setup. The model I’m most proud of is this remix: Original Prusa Enclosure RepBox 2.5 Stand.

Backstory: I originally found this stand, but the top wasn’t wide enough to fit my newer RepBox. So I grabbed measurements from that model I printed and rebuilt the geometry in OpenSCAD (I’m honestly not great with Fusion), then published an updated version that fits the 2.5.

- What it solved: a stable, tidy perch for the Repbox that matches the Original Prusa Enclosure.

- Why it works: clean tolerances, orientation‑friendly faces, fast print with no weird supports.

- What I learned: small, thoughtful tweaks often beat big redesigns—and documenting those tweaks helps everyone.

What’s a remix? On Printables (and 3D printing in general), a remix is a derivative design that builds on someone else’s model. You credit the original and clearly state what changed (dimensions, features, materials, etc.). Remixing is how we iterate together—adapting good ideas to new hardware, use cases, or materials without starting from scratch. Please remember to honor the license on the model you are remixing.

Seeing other people’s Makes on this one has been especially fun—different color combos, different setups—and it’s a great reminder that useful models travel far once they’re out in the world.

Thangs: when I need to search the entire internet

Sometimes I don’t want a single listing; I want the closest geometry match hiding anywhere online. That’s where Thangs shines.

- Geometry‑aware search: You can hunt by shape and find related designs across multiple platforms. It’s wild.

- Great for engineering parts: Need a parametric base, a STEP file, or something to remix in OpenSCAD? Thangs is a solid starting point.

- Practical tip: Add dimensions and hardware to your searches—“92mm fan,” “M4 heat‑set insert,” “10‑inch rack.” It filters out the noise fast.

I use Thangs like a metal detector. Sweep wide, find candidates, then click through to the original hosting page to vet the listing properly.

Thingiverse: the OG archive still worth a look

Is it perfect? Nope. Is it still packed with gems? Absolutely. Thingiverse has years of community projects, remixes, and problem‑solving oddities that never made it anywhere else.

- Go for “Makes” and remixes: Sort or scan for projects with lots of real‑world prints.

- Read the comments: That’s where the hidden settings and gotchas hide.

- Grab source when you can: STEP, SCAD, or DXF? Save yourself time if you plan to tweak.

Treat Thingiverse like a dusty but beloved toolbox: dig a little, and you’ll find the exact adapter you needed.

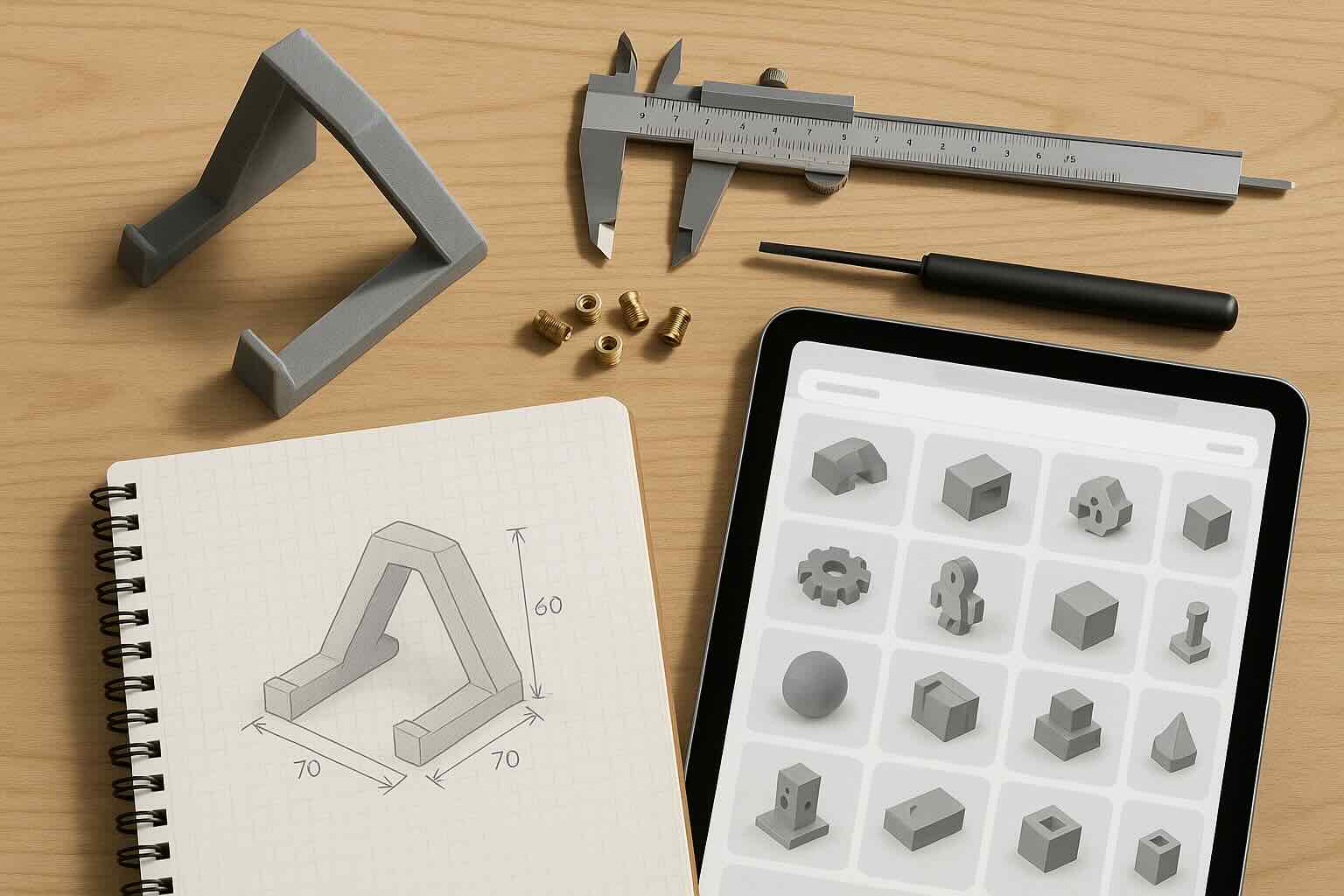

How I vet a model before I print (save time + plastic)

Most bad prints can be traced back to missing details. Here’s the fast checklist I run through:

Quality signals

- Clear description of intent (what problem does this solve?)

- Recommended material + layer height + infill + orientation

- Real photos in the “Makes” section

- Fastener callouts (M3 vs M4, length, heat‑set inserts)

- Notes on tolerances or required scaling

Files that help

- 3MF project file with orientation baked in

- STEP/SCAD if edits might be needed

- A simple diagram or exploded view if assembly is non‑obvious

Red flags

- Vague description like “works great!” with no settings

- No photos, no makes, no comments

- External download links with zero context

- STL scaled weirdly

Mini test routine

- Print a small fit‑check piece at draft settings

- Use a tolerance coupon to validate press‑fits

- If hardware is involved, test with the actual screws/inserts before committing to a multi‑hour print

Pro search tips that actually help

- Add numbers. Dimensions turn a vague idea into a laser‑targeted query.

- Use synonyms. “Drawer divider” vs “organizer,” “guy ring” vs “mast ring,” etc.

- Follow trusted creators. When someone nails printability, stick with them.

- Save Collections. Build your own library by theme: racks, radio, shop, home, etc.

- Leave a Make. Your photo + note saves the next person hours.

Contributing back: from downloader to designer

You don’t have to be a CAD wizard to help the community. Here’s an upload checklist that makes your model genuinely useful:

- Tell the story. One paragraph on the problem you solved.

- List the hardware. Thread sizes, lengths, inserts, nuts.

- Share print settings that matter. Orientation, supports on/off, perimeters, infill range.

- Add photos in context. Seeing it installed is half the battle.

- Tag smartly. Materials (ASA/PETG), dimensions, printer/slicer, and the use case (rack, mast, cable, etc.).

On Printables, those details get rewarded—literally with points, and socially with more Makes. It all adds up.

Quick callout — simple models can be hits: My BNC Brace for TRuSDX is a tiny, single‑purpose part that prints fast and punches above its weight. It’s a great example of how solving a small, specific problem (reducing connector stress on a portable radio) can resonate with a community. Useful beats flashy—every time.

My everyday workflow (fast, repeatable, low drama)

- Design in OpenSCAD when I want parametric control; export clean STLs or straight to 3MF with suggested settings.

- PrusaSlicer for projects: orientation locked in, per‑model modifiers ready, profiles tuned for strength vs speed.

- Version control with Git for the .scad and notes; ignore bulky STLs in a

.gitignore. - Publish to Printables with a clear story, photos, BOM, and links back to any related blog post.

This keeps everything portable. If I open the project months later, I know exactly what to do.

FAQs

Is Thangs a host or a search engine? Both. I use it primarily as a discovery tool and then vet the original listing.

What’s the difference between STL and 3MF? STL is just geometry. 3MF can carry project context—orientation, parts, and slicer settings—so you’re not guessing.

Can I sell prints from files I find? Read the license. CC‑BY usually allows commercial use with attribution; -NC means non‑commercial; -ND means no derivatives. When in doubt, ask.

What’s a “Make” and why should I add one? A Make is your real‑world print with photos and notes. It helps the creator improve and helps the next printer get a good result the first time.

Wrap‑up + where to go next

Different sites shine for different jobs. I’ll browse Thangs when I need to sweep the whole internet. I’ll dip into Thingiverse for remixes and legacy projects. But day‑to‑day, Printables is where I live—because the community features, the points and contests, and that slick Open in PrusaSlicer workflow keep me moving.

If you want more of the mindset behind all this, read my thoughts on Rethinking MYOG here.

If you want a concrete example, here’s the 10‑inch rack mount project.

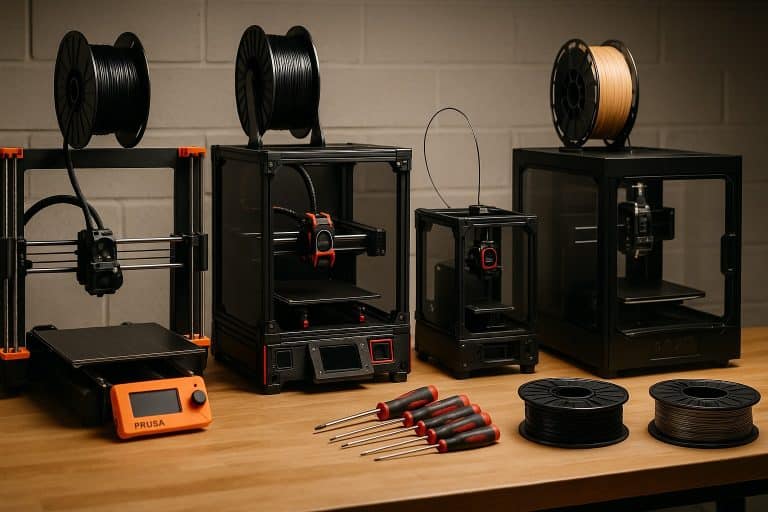

If you are interested in getting your first 3D printer, check out my guide here.

If you want to poke around my projects, I’m @techis on Printables (yep, different name than the blog, same person): https://www.printables.com/@techis. If you print something, I’d love to see your Make. It’s the best kind of feedback.