Why Sewing Machine Maintenance Matters (Especially for MYOG Projects)

Sewing your own gear puts your machine through some serious work. Whether you’re building dog leashes, field pouches, or modular bags for portable ham radio ops, heavy-duty threads and multiple fabric layers generate extra heat, tension, and lint. That’s why regular maintenance isn’t just helpful — it’s essential.

In this guide, I’ll walk you through simple, effective ways to keep your sewing machine running smoothly so you can focus on creating gear you trust in the field.

Important: Every machine is different. Always consult your owner’s manual for specific instructions on cleaning, oiling, and tension settings. Don’t have the manual? Many are available online via the manufacturer’s website or sewing forums.

Basic Maintenance Checklist for MYOG Sewing

Here are five key areas to stay on top of:

1. Clean the Bobbin Area and Feed Dogs

- Remove the throat plate and gently clean out lint and thread fragments.

- Use a soft brush or a small vacuum attachment — never compressed air, which can push debris deeper.

- Clean around the feed dogs to prevent stitching issues.

2. Change Your Needle Regularly

- For heavy-duty projects, change your needle every 1–2 projects.

- Dull or bent needles can cause skipped stitches, noisy operation, or fabric damage.

- Keep spare size 16 or 18 needles on hand for thicker webbing and canvas.

3. Oil Your Machine (If Required)

- Many mechanical machines need occasional oiling — follow your manual exactly.

- Use only sewing machine oil. Never use WD-40, 3-in-1, or household oils. These can gum up your internal parts.

- Apply 1–2 drops in the indicated spots and run the machine briefly without thread to distribute.

4. Check Tension and Thread Paths

- If stitches look uneven or thread breaks often, it may be time to clean and reset your tension.

- Rethread your top thread and bobbin to rule out misalignment.

- Always use good-quality thread appropriate for your project.

5. Wipe Down the Machine Exterior

- Dust and wipe with a soft cloth to remove lint from thread spools and guides.

- A tidy machine helps you spot issues early and keeps your space feeling good to work in.

If you’re not comfortable doing the cleaning or oiling yourself, many sewing machine repair shops offer professional maintenance services. Taking your machine in for a tune-up once or twice a year can be a great way to keep it running at its best.

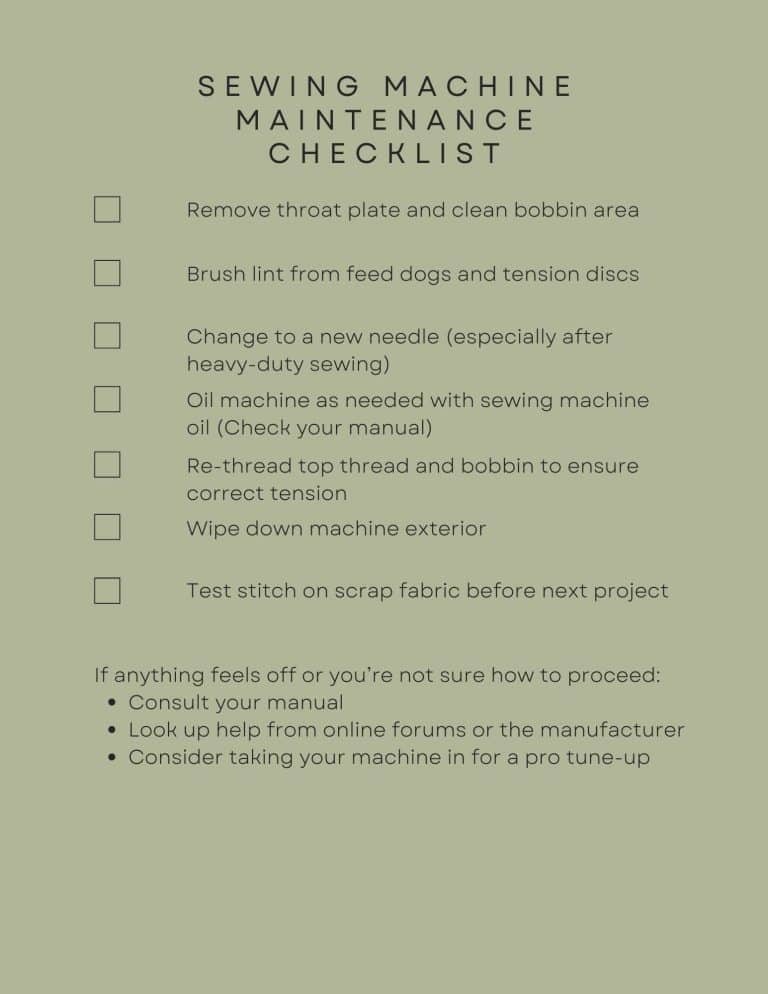

Quick Maintenance Checklist

Use this checklist before or after every few projects to keep your machine humming:

Pro Tips for MYOG Sewers

- Maintenance Day: After every 1–3 projects (especially with webbing or heavy thread), set aside 15 minutes for a light clean and checkup.

- Keep tools handy: Store a lint brush, screwdriver, spare needles, and machine oil in a small tin near your machine.

- If in doubt, don’t force it: Strange noises, fabric drag, or inconsistent stitches are all signs your machine needs attention.

Where to Find Replacement Manuals

If your machine didn’t come with a manual, don’t panic. Check these spots:

- Manufacturer’s website (Singer, Brother, Juki, Janome, etc.)

- Online sewing communities (like r/sewing or vintage machine forums)

- eBay or sewing machine part resellers

Keep Creating with Confidence

A clean, well-maintained sewing machine gives you confidence to tackle tough builds. Whether you’re sewing a rugged dog collar or field-ready POTA gear, regular care keeps your stitches clean and your machine happy.

If you haven’t started building your own MYOG gear yet, check out my 5 Easy MYOG Projects You Can Sew or get prepped with How to Plan and Measure Your MYOG Projects.

Have a favorite maintenance trick? Tag @printpresssew and use #MYOGJourney to share your setup!